CRANE RUNWAYS

Free standing, ceiling mounted, or semi-free standing

Free standing, ceiling mounted, or semi-free standing

Top Running Workstation Bridge Crane Runway

Freestanding Runway

The Freestanding runway stands on its own – its design resists lateral and longitudinal forces unaided. Braces to other support structures simply aren’t necessary.

This independence brings versatility: the system’s just as comfortable outdoors as indoors. The bridge crane runs on rails mounted to the top of the runway beams, maximizing the available hook height.

Top Running Freestanding bridge crane runways are also able to handle higher capacities than underhung models.

Freestanding Runway

The Freestanding runway stands on its own – its design resists lateral and longitudinal forces unaided. Braces to other support structures simply aren’t necessary.

This independence brings versatility: the system’s just as comfortable outdoors as indoors. The bridge crane runs on rails mounted to the top of the runway beams, maximizing the available hook height.

Top Running Freestanding bridge crane runways are also able to handle higher capacities than underhung models.

Semi-Freestanding Runway

When a new or existing building has enough reserve capacity to resist the longitudinal (along the length of the crane runway) and lateral (across the width of the runway) forces, Service Crane can attach the columns and runways to these buildings, reducing the amount of steel required to produce an overhead crane system.

Header-Braced Crane Runway

The runway is supported by the freestanding support columns, each pair tied together by a header. Header-braced systems are ideal when the lowest obstruction in the building is high enough that it does not limit the hook height.

This runway type is easily expandable, and can handle multiple bridge crane systems.

Header-Braced Crane Runway

The runway is supported by the freestanding support columns, each pair tied together by a header. Header-braced systems are ideal when the lowest obstruction in the building is high enough that it does not limit the hook height.

This runway type is easily expandable, and can handle multiple bridge crane systems.

Knee-Braced Runway

Knee-braced crane runways have supports that mount directly to a 6 inch concrete slab or reinforced concrete footers. These low maintenance runway crane systems offer unbeatable hook height when ample floor space is available.

Underhung Freestanding Runway

AmeriCrane underhung freestanding runways feature a bolt-together construction which doesn’t require a certified welder for assembly.

One of the major advantages of an underhung crane is its ability to interlock with a fixed spur, crossover, and adjacent cranes.

This interlocking capability allows a load to be transported throughout the plant system without the need to set it down, thereby eliminating re-handling.

Underhung Freestanding Runway

AmeriCrane underhung freestanding runways feature a bolt-together construction which doesn’t require a certified welder for assembly.

One of the major advantages of an underhung crane is its ability to interlock with a fixed spur, crossover, and adjacent cranes.

This interlocking capability allows a load to be transported throughout the plant system without the need to set it down, thereby eliminating re-handling.

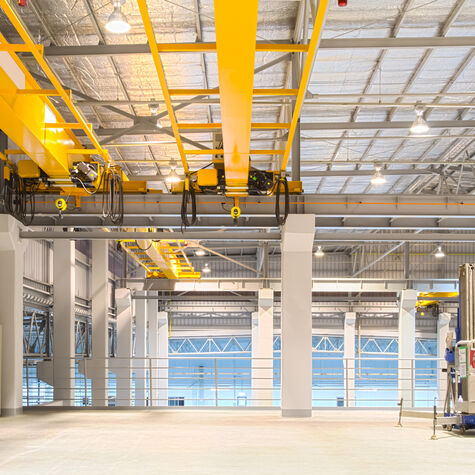

Underhung Ceiling-Mounted Runway

AmeriCrane underhung ceiling-mounted runways feature overhead crane runways that attach directly to the ceiling or roof structure of a building.

Ceiling-mounted, underhung systems are extremely versatile and can be used to easily transfer loads from one bay to another with the use of transfer switches.

Underhung ceiling-mounted crane runways allow for the utilization of entire floor space under the crane runway as well.